测试软件

做用户心中最好的测量软件Be the best measurinjg software for customers

FM-3D

自动测量软件是开发人员结合十余年计量行业及软件工作经验,精心研发的专业的二维测量软件。设计原则是:操作简单,功能强大,稳定可靠,维护方便。主要借鉴了国外知名软件,如美国OGP的MeasureMindPlus多传感器软件,及美国的MicroVu公司的测量软件,并结合国内的情况,博采众长,优化组合.精心研发而成。Automatic measuring software is a professional two-dimensional measuring software developed by the developer with more than ten years of experience in measurement industry and software.The design principle is: operate simply , powerful, stable and reliable, maintain easily.Mainly draw lessons from well-known foreign software, such as the United States OGP MeasureMindPlus multi sensor measuring software,and the MicroVu company’s software in the United States, combined with the domestic situation, learn widely from others'strong points,carefully optimized combination , elaborately research and development.

全备的元素测量功能,界面方便快捷。Multiple element measurement function, convenient interface.

能测12种元素(点、直线、圆、圆弧、椭圆、矩形、槽形、O形环、距离、角度、开云线、闭云线)Can measure 12 elements(Point, line, circle, arc, ellipse, rectangle, groove, O ring, distance, angle,open cloud line and close cloud line)

特点:Feature

测量方法多样(自动判别测量、采点测量﹐对比测量、公差对比测量、预置元素),可以满足用户不同需求,大大提高使用的方便性和测量精度。Various measuring methods (automatic discrimination measurement, point mining measurement, comparative measurement, tolerance comparison measurement, preset elements) can meet different users’ demands , and greatly improve the convenience and accuracy of measuring.

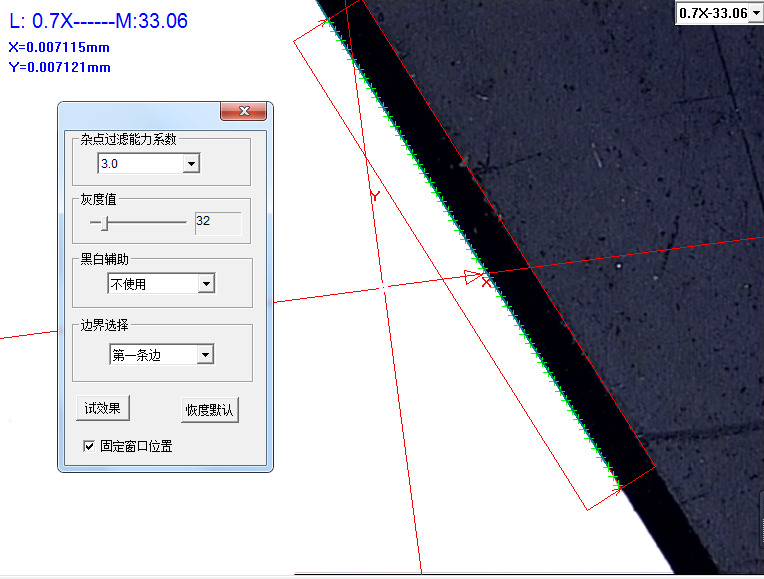

单点采集方法有多种﹕可鼠标采点,十字线寻边采点,放大采点。There are many kinds of single point collection methods: mouse picking point, reticle edge searching point, enlarge picking point.

能测量闭合云线的周长,面积及重心,使用三次插值算法,为目前最准确测量云线的方法。It can measure the perimeter, the area and the center of gravity of a closed cloud line, and use the three interpolation algorithm as the most accurate method of measuring the cloud line at present.

可以进行框选测量多圆,快速,准确的一次测量多个圆。Can use frame selection to measure many circles,rapidly, accurately measure many circles at a time.

测量的数据可以保存为DXF档,或.BMP图片,及用户程序格式。The measured data can be saved as DXF, or.BMP, and user program formats.

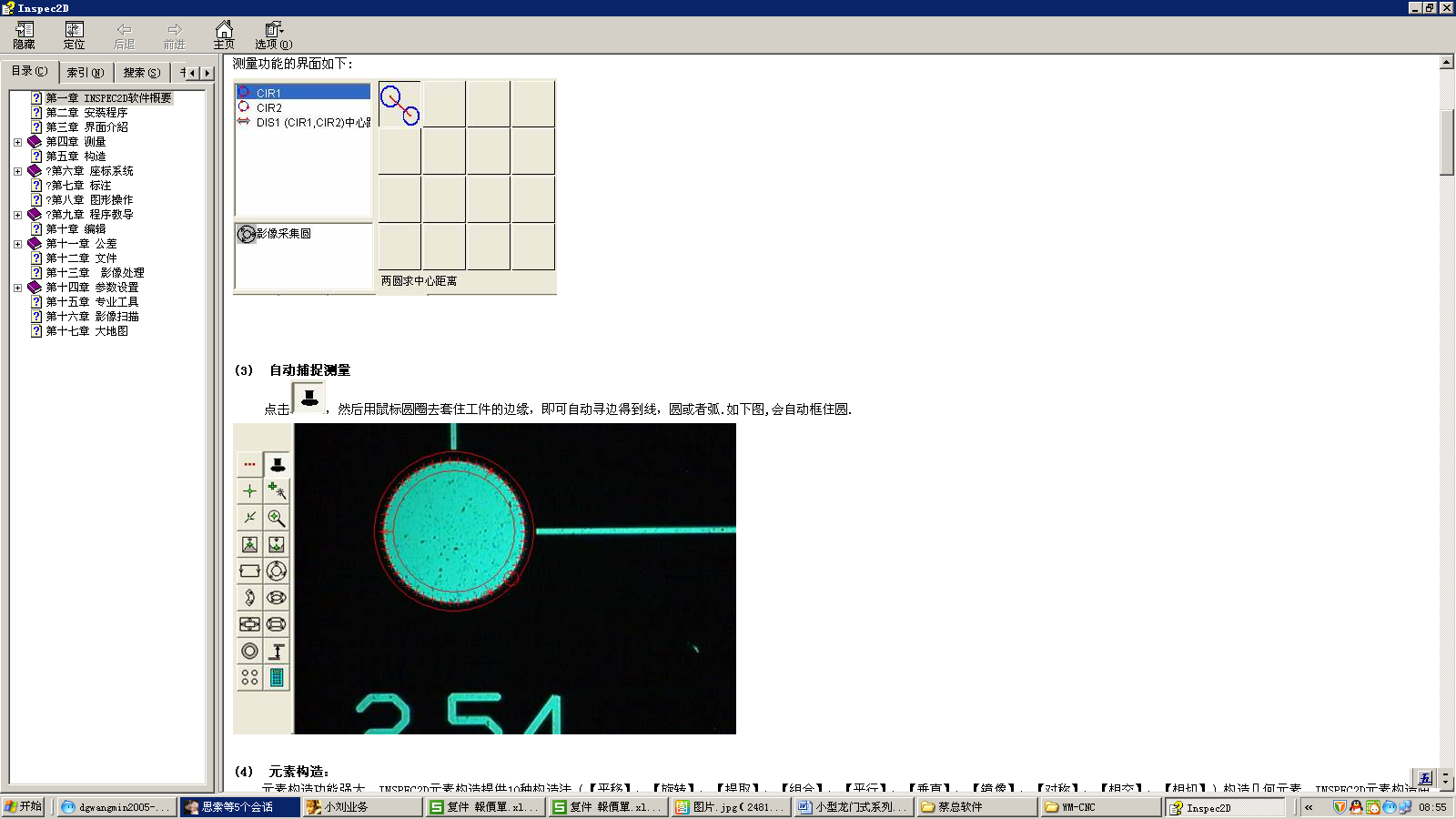

自动捕捉测量Automatic capture measurement

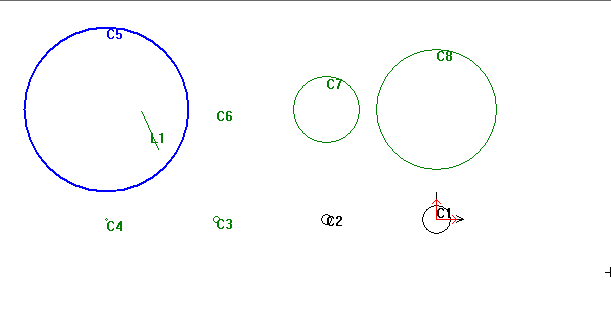

鼠标圆圈去套住工件的边缘,即可自动寻边得到线,圆或者弧.如下图,会自动框住圆.The mouse circle to trap the edge of the workpiece, you can automatically find the edge to get the line, circle or arc. As following picture,will automatically frame the circle.

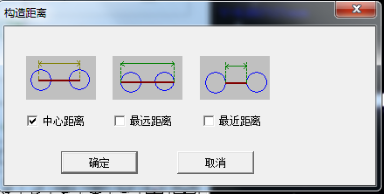

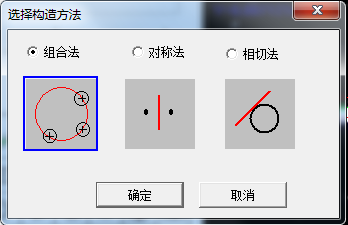

元素构造:Structure elements

元素构造功能强大。FM-3D元素构造提供10种构造法(【平移】、【旋转】、【提取】、【组合】、【平行】、【垂直】、【镜像】、【对称】、【相交】、【相切】)构造几何元素。Elemental structure is powerful.(The WM-3D

element structure provides 10 kinds of construction method (【translation】 ,【rotation】, 【extraction】 【combination】 ,【parallel】 【vertical】【mirror】【symmetric】 【tangent】,【intersection】 ) to construct

geometric elements.)

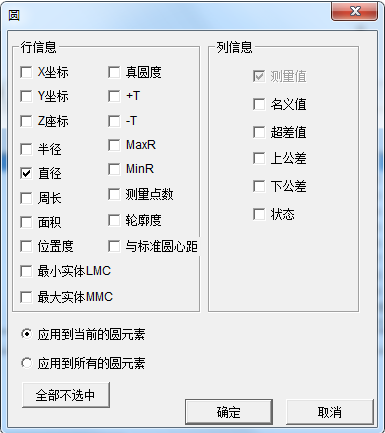

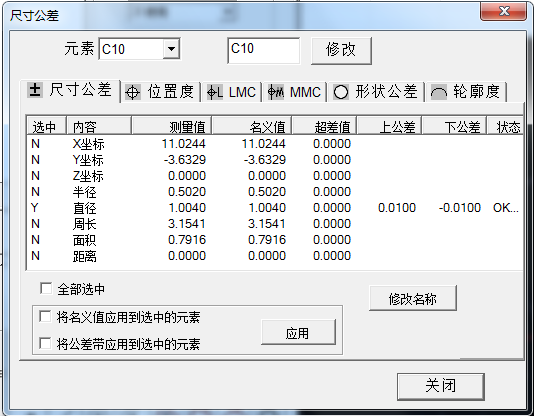

显示结果丰富Display rich results

显示各种元素的测量结果﹐其信息量大﹐能满足各种客户的需要。并可设置哪些内容显示,哪些内容不显示﹐也可以单个元素进行单独设置其显示信息。也可对同类元素进行设置,下图是圆元素的显示信息设置对话框。The measurement results of various elements show that they are large enough to meet the needs of various customers. You can also set what displays, what does not appear, or you can set up individual elements to display information. You can also set the similar elements, and the following is the display information settings dialog box of the circle element.

坐标系统Coordinate system

可根据图纸建立多重工件坐标系,实现各坐标系的坐标变换,能方便地实现直角坐标系与极坐标系之间的相互转换,能实现各工件坐标系的存储和调用。The coordinate system of multiple workpieces can be set up according to the drawing ,realize the coordinate transformation about each coordinate system, can conveniently realize interconversion between the rectangular coordinate system and the polar coordinate system , and realize storage and transfer each workpiece coordinate system .

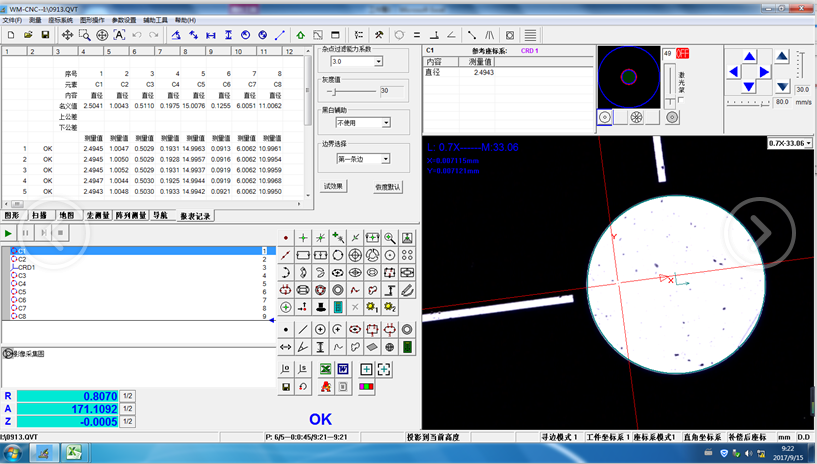

程序批量测量Program batch measurement

不受限制的用户程序记录、编辑、保存、呼出功能。FM-3D用户程序可以记录﹑编辑所有的用户动作,实现复制测量,大幅提高测量效率。Unrestricted user program has recording, editing, and saving,exhalation function. WM-3D user program can record and edit all user actions, achieve replication measurements, and greatly improve measuring efficiency.

简易的用户程序教导方式,可复制教导步骤,强大的视觉化编辑功能,方便批量检测。Simple user program instruction method, can copy teaching steps, powerful visual editing function, convenient batch inspection.

FM-3D使用教导程序模式记录用户程序。用户在第一次测量工件时,自动记录工件测量的用户程序,记录的用户程序能被保存到电脑以便能再次打开重新运行。WM-3D uses a tutorial program to record user programs. When the user first measures the workpiece, automatically records user programs of the workpiece’s measurement , and the recorded user program can be saved to the computer so that it can be opened again and rerun.

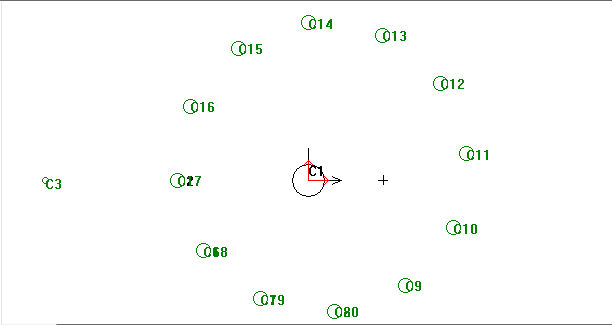

智能型方向指示器,指示下一步要测量的元素的位置,方便用户寻找目标。Intelligent direction indicator indicates the location of the elements to be measured next, so that the user can conveniently find the ta rget .

可以设置是否在运行用户程序过程中进行自动对焦,在自动测量过程中,可以进行手动测量。You can set whether auto focus during run user operation, and use manual measurements during automatic measurement.

可以重新测量一个元素,以改变其测量方法,也可以编辑修改其测量的倍率,光源,寻边方法等。Can remeasure an element to change its measurement method, and also can through editing and modify to change its measuring magnification, light, edge finding method, etc..

下图是通过平移和旋转建立的两个用户程序:The following diagram is the two user program created by translation and rotation:

公差Tolerance

完善的尺寸公差计算能力,可设置默认的公差带。Perfect dimensional tolerance calculation ability, can set the default tolerance zone.

符合国标的形位公差计算能力,能计算形状公差,真直度,圆、弧的真圆度。Accord with the national standard geometric tolerance calculation, can calculate shape tolerance , the true straightness, circleand arc true roundness.

位置公差计算包含位置度、平行度、垂直度、倾斜度及同心度﹐对称度。超差能自动报警,并以红色警示。Positional tolerance calculation includes position, parallelism, perpendicularity, inclination and concentricity, symmetry. The super difference can automatically alarm and red alert.

寻边模式Seek edge model

影像自动寻边模式,针对表面影像特点设计不同的寻边模式:普通法,密度法,网板法,包括软件预制的:模式一,模式二,模式三,以及去除人工杂点,除杂点设置:色彩过滤等方法,以便自动测量,准确测量。Image automatic edge searching model,, set different edge models according to image characteristics : normal method, density method, mesh method, including software reset: mode one, mode two, mode three, and the removal of artificial noise and impurity settings: color filter and ect, ensure automatic measurement and accurate measurement.

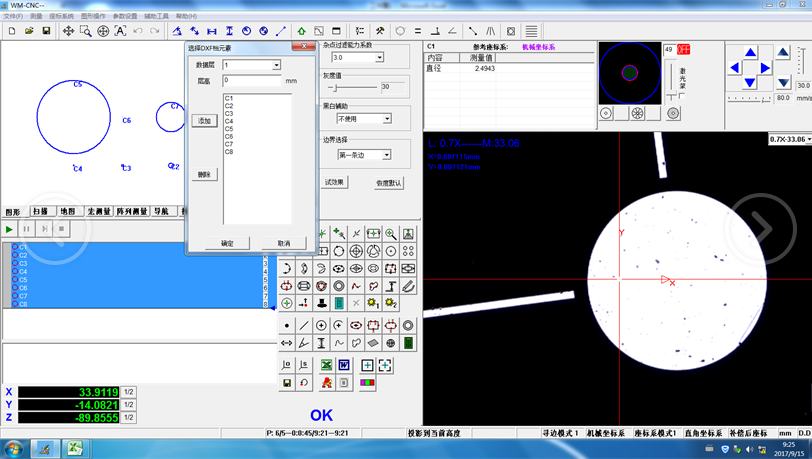

DXF档导入编程 DXF file import programming

导入DXF档后,软件会提示用户一步一步操作,当建立好工件座标系后,则DXF档导入产生用户程式完成。软件会自动产生名元素的名义值。当运行用户程式时,将产生DXF档与影像贴图对比。After you import the DXF file, the software prompts the user step by step. When the workpiece coordinate system is established, the DXF file is imported to produce the user program. The software automatically generates the nominal value of the name element. When running the user program, the DXF file is generated and compared to the image map.

语言转换:Language transformation

现已准备好的“中文简体”、“中文繁体”与“英文”三种屏幕对话语言已能满足绝大多数用户的需求。系统默认的语言与计算机操作系统相一致。用户可通过“参数设置”实现中英文切换。The three language of screen dialogue, "Chinese simplified", "Chinese traditional" and "English", have been prepared, which can meet the needs of the overwhelming majority of users. The default language of the system is consistent with the computer operating system. Users can switch between Chinese and English by parameter setting.

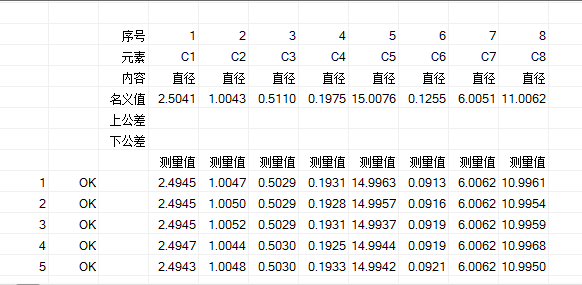

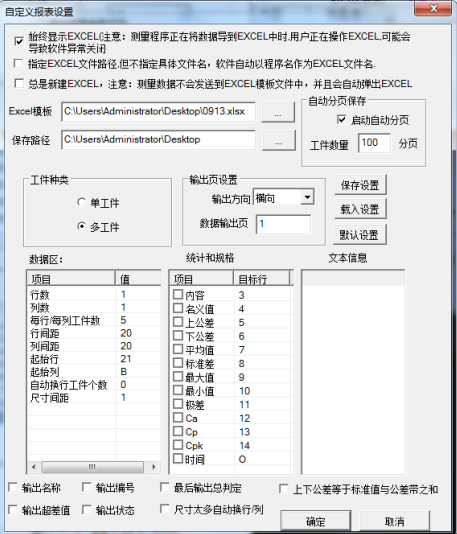

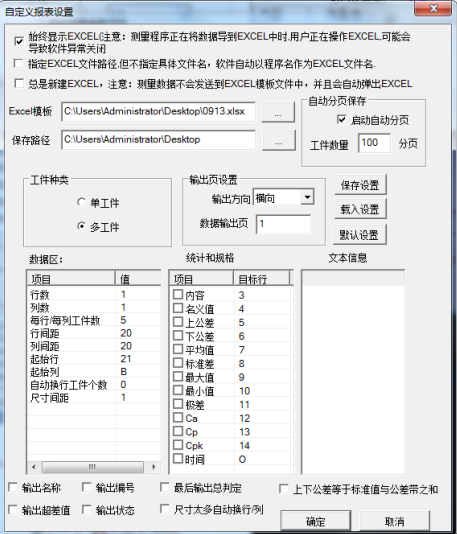

报表功能Report function

测量数据可以导出到Excel、Word,AutoCAD,TXT中。Measurement data can be exported to Excel, Word, AutoCAD, TXT.

运行用户程序时,可将数据按行或列方式导入到Excel中。When you run a user program, you can import data in rows or columns into the Excel.

导入到报表中时,可选择是否导出图形和位图。When you import into a report, you can choose whether to export graphics and bitmaps.

下图是同一个工件图片,测量五次后,自动导出到Excel中的报表:The following image is the same work piece,after five measurements, the report is automatically exported to Excel:

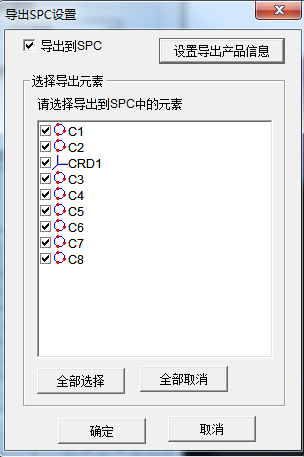

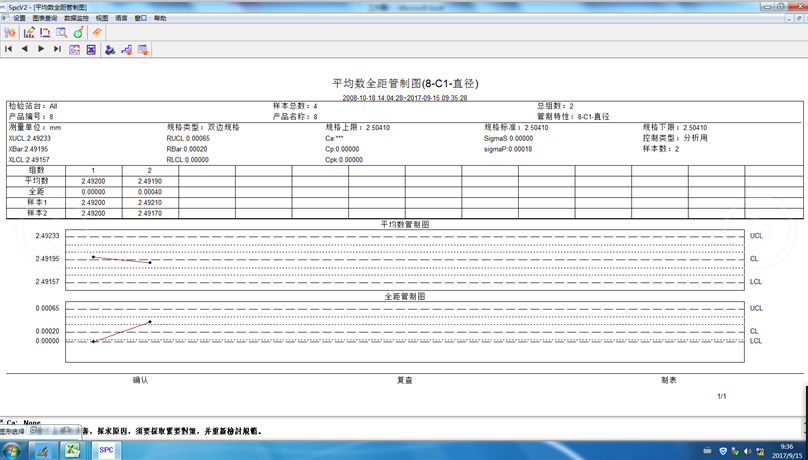

在线SPC功能Online SPC functio

FM-3D提供独立的,专业的SPC软件﹐进行测量数据的后续处理,测量软件与SPC软件无缝连接﹐测量软件完成测量后,自动将数据导入到SPC数据库﹐不需要人工再输入﹐所有的管制界限的设置全部在测量软件中完成﹐SPC软件无需再设置﹐从而大大提高效率。SPC提供制程用和分析用管制图。提供的管制图有:平均数全距管制图,平均数标准差管制图,中位数全距管制图,个别值与移动平均值管制图,直方图,cpk推移图,规格标准差管制图,制程标准差管制图,标准差比较图,制程建议分析图等。对生成的图形可以利用八大判定规则进行判定。其图表及数据可打印及导入到Excel中。WM-3D provides independent, professional SPC software, for the subsequent processing of measurement data, seamless connection between measuring software and SPC software, measuring software finish measuring, data automaticaly export into SPC database, without manual input, the control limits all the settings are all done in the measurement software, SPC software is not required to be arranged, so as to improve the efficiency of. SPC provides control charts for manufacturing procedure and analysis. The control chart: the mean range control chart, the average standard deviation control chart, median range chart, individual value and moving average control chart, histogram, Cpk graph, standard deviation control chart, process standard deviation control chart, standard deviation comparison chart, process analysis chart etc.. The generated graphics can be determined by the eight decision rules. Its diagrams and data can be printed and imported into Excel.

测量品质源于尖端科技Measuring quality comes from cutting-edge technology

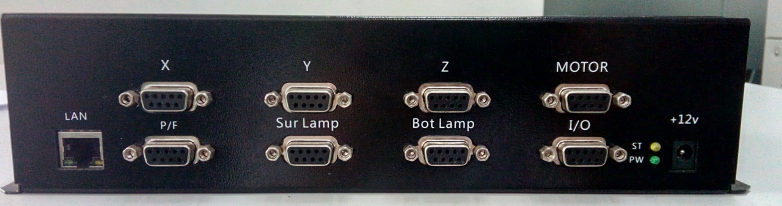

电控系统Electronic control syste

电控系统,在精密测量行业,本公司是有自主研发控制器能力的民族企业,本公司电控系统分为手动机专用控制系统和CNC自动机专用控制系统,满足各种机型所需。The electric control system, in precision measurement industry,our company is national enterprises which can independent research and develop controller , our company's electronic control system is divided into manual machine dedicated control system and CNC dedicated control system to meet a variety of models required.

光学系统Optical system

本公司测量仪提供轮廓光、表面光、同轴光三种光源;可以根据不同类型工件,提供灵活的照明方式,清晰度高,测量更精确。Our company provides three kinds of light: profile light, surface light and coaxial light. It can provide flexible lighting according to different types of workpieces, with high clarity and accurate measurement.

可配探针

可配激光

- 上一篇:中高端模具机床需要明确未来发展方向 2019/2/22

- 下一篇:没有啦